Kumvetsetsa Thin-Film Technology

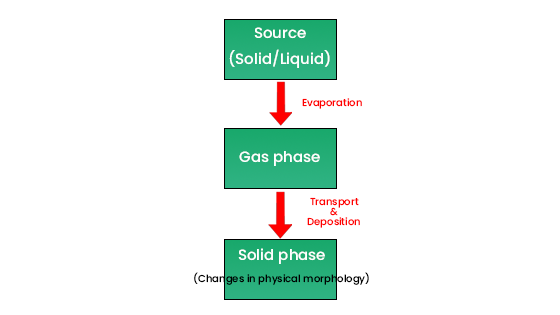

Ukatswiri wamakanema opyapyala umaphatikizapo kuyika zinthu zowonda (nthawi zambiri kuyambira ma nanometer ochepa mpaka ma micrometer ochepa wokhuthala) pagawo. Zigawozi zimatha kupangidwa ndi zitsulo, semiconductors, insulators, kapena zida zina, ndipo zimagwiritsidwa ntchito popanga zida zamagetsi zamagetsi. Tekinoloje iyi ndiyofunikira kwambiri popanga zida zamagetsi chifukwa imathandizira kulondola kwambiri komanso magwiridwe antchito azinthu. Thin-film deposition imachitika kudzera mu physical vapor deposition (PVD) kapena chemical vapor deposition (CVD), kuwonetsetsa kuti chinthu chomaliza chimagwira ntchito bwino.

Kukula kwaukadaulo wamakanema opyapyala kudayamba chapakati pazaka za m'ma 1900 pomwe kupita patsogolo kwakukulu kudapangidwa mu sayansi ya zinthu ndi njira zopangira vacuum. Poyambirira, ukadaulo wamakanema owonda unkagwiritsidwa ntchito makamaka mumakampani opanga ma semiconductor popanga ma transistors ndi mabwalo ophatikizika. Pamene ukadaulo ukupita patsogolo komanso kufunikira kukukulirakulira, kuchuluka kwaukadaulo wamakanema opyapyala kudakula mwachangu. Masiku ano, amagwiritsidwa ntchito kwambiri popanga masensa, zokutira zowoneka bwino, ma cell a solar, hard disk drives, ndi zokutira zotsutsana ndi kutu, pakati pa ena. Mwachitsanzo, popanga masensa, umisiri wa filimu yopyapyala umagwiritsidwa ntchito kupanga masensa amphamvu, masensa a gasi, ndi masensa a kutentha, omwe amadziwika ndi kukhudzika kwakukulu ndi kulondola. Kuphatikiza apo, kugwiritsa ntchito ukadaulo wamafilimu opyapyala m'makina a microelectromechanical (MEMS) ndi nanotechnology ikukulanso, kupereka chithandizo chofunikira pazatsopano ndi chitukuko m'magawo awa.

Zofunikira zazikulu zaukadaulo wamakanema opyapyala zimaphatikizapo kulondola kwake, kusinthasintha, komanso kuthekera kophatikiza zinthu zambiri. Kulondola kwambiri kumathandizira ukadaulo wamakanema opyapyala kuti azitha kuyeza molondola kwambiri pakasinthidwe kakang'ono, zomwe ndizofunikira kwambiri pazida monga zowonera kupanikizika zomwe zimafunika kuwongolera miyeso yolondola yapanthawi yake m'malo osiyanasiyana. Kusinthasintha kwamakanema opyapyala kumawalola kuti azitha kutengera magawo osiyanasiyana ndi zosowa zamagwiritsidwe ntchito, ndikupangitsa kuyika pazigawo zosiyanasiyana monga silicon, galasi, zitsulo, ndi mapulasitiki, potero kukwaniritsa ntchito zingapo. Kuphatikiza apo, ukadaulo wamakanema owonda amatha kuphatikizidwa ndi matekinoloje ena ndi zida kuti apange zida zophatikizika ndi ntchito zingapo. Mwachitsanzo, kuphatikiza tekinoloje yamakanema opyapyala ndi MEMS kumatha kupanga tinthu tating'ono tating'ono tating'ono komanso topepuka komanso tomvera komanso odalirika.

Ukadaulo wa kanema wowonda umathanso kuphatikiza magwiridwe antchito angapo mu chipangizo chimodzi, kutanthauza kuti kuzindikira, kuyeza, ndi kusanthula deta kumatha kukwaniritsidwa nthawi imodzi mkati mwa filimu yopyapyala, kufewetsa kapangidwe kake ndi kupanga kachipangizo. Kuthekera kophatikiza kumeneku sikumangowonjezera magwiridwe antchito ndi kudalirika kwa chipangizocho komanso kumachepetsa ndalama zopangira komanso zovuta. Pakukula kwa masensa opanikizika, ukadaulo wafilimu woonda kwambiri ukhoza kupititsa patsogolo magwiridwe antchito, kuwalola kuti azigwira ntchito mokhazikika m'malo osiyanasiyana ovuta.

Kuphatikiza kwa Thin-Film Technology mu Pressure Sensors

Kuphatikizika kwaukadaulo wamakanema opyapyala m'masensa opanikizika kumafuna kupititsa patsogolo magwiridwe antchito, kuchepetsa kukula, ndikuwonjezera chidwi. Mwa kuwongolera bwino zinthu zakuthupi ndi makulidwe osanjikiza, ukadaulo wamakanema owonda kwambiri umapangitsa kupanga masensa apamwamba kwambiri kukhala kotheka. Kuphatikizana kumeneku sikumangowonjezera magwiridwe antchito onse a masensa komanso kumabweretsa zabwino zambiri pazinthu zingapo zofunika.

Choyamba, ukadaulo wamakanema owonda umathandizira kuti masensa ang'onoang'ono aziwoneka. Masensa amtundu wachikhalidwe nthawi zambiri amakumana ndi malire pakukula ndi kulemera kwake, pomwe ukadaulo wamakanema owonda umalola kupanga masensa ang'onoang'ono, opepuka popanda kusokoneza magwiridwe antchito. Izi ndizofunikira makamaka pamapulogalamu omwe ali ndi malo ochepa kapena omwe amafunikira mayankho opepuka, monga zida zamankhwala ndi MEMS.

Kachiwiri, masensa amafilimu opyapyala amapambana pakuwonjezera chidwi. Ukadaulo wa kanema wowonda umatha kuzindikira kusintha kwakanthawi kochepa kwambiri, kupangitsa masensa awa kukhala opindulitsa m'malo omwe amafunikira miyeso yolondola. Mwachitsanzo, poyang'anira makina opanga mafakitale komanso kuwunika kwachilengedwe, zowunikira zowonda zamakanema zimatha kupereka chidziwitso cholondola, potero kumapangitsa kuti magwiridwe antchito azikhala odalirika komanso odalirika.

Kuphatikiza apo, ukadaulo wamakanema owonda umapangitsa kudalirika komanso kulimba kwa masensa opanikizika. Kufanana kwapamwamba ndi kukhazikika kwa zigawo zoonda-filimu zimatsimikizira kuti zimagwira ntchito nthawi yayitali. Poyerekeza ndi masensa achikhalidwe, masensa amafilimu opyapyala amatha kukhalabe ndi magwiridwe antchito abwino ngakhale m'malo ovuta kwambiri, kuwapangitsa kuti azigwiritsidwa ntchito kwambiri m'magawo monga azamlengalenga ndi mafakitale amagalimoto.

Poyerekeza ndi njira zachikhalidwe, ukadaulo wamakanema owonda umapereka njira yopepuka, yaying'ono, komanso yovuta kwambiri. Masensa amtundu wamba nthawi zambiri amakumana ndi zovuta kukula kwake, kulemera kwake, komanso kulondola, pomwe ukadaulo wamakanema opyapyala, okhala ndi zinthu zapamwamba kwambiri komanso njira zopangira, zimapambana izi. Masensa amafilimu opyapyala samangokhala ndi maubwino kukula ndi kulemera kwake komanso amapambana kwambiri ndi masensa achikale potengera kulondola komanso kumva. Ubwinowu umapangitsa ukadaulo wamafilimu oonda kukhala gawo lofunikira pakukula kwaukadaulo wamakono wa sensa.

Zipangizo za Thin-Film Pressure Sensors

Kusankhidwa kwa zida zamasensa owonda kwambiri amafilimu ndikofunikira chifukwa zida izi zimakhudza mwachindunji magwiridwe antchito ndi kudalirika kwa masensa.

Zida Zogwirizana

Zida zodziwika bwino zomwe zimagwiritsidwa ntchito m'masensa amagetsi opyapyala amaphatikiza zitsulo monga golide, platinamu, ndi aluminiyamu, zomwe zimadziwika chifukwa champhamvu kwambiri komanso kukana dzimbiri. Golide, ngati chinthu chochititsa chidwi kwambiri, nthawi zambiri amagwiritsidwa ntchito m'magawo a electrode a masensa kuti atsimikizire kulondola komanso kukhazikika kwa kufalitsa chizindikiro. Platinamu, chifukwa cha kukhazikika kwake kwamafuta komanso kukana kwa okosijeni, imagwiritsidwa ntchito kwambiri m'masensa am'madera otentha kwambiri. Aluminiyamu, pokhala wopepuka komanso kukhala ndi ma conductivity abwino, amagwiritsidwa ntchito nthawi zambiri pamasensa omwe amafunikira kuwongolera kulemera. Kuphatikiza apo, zida za semiconductor monga silicon ndi germanium zimagwiritsidwa ntchito kwambiri pamasensa opaka mafilimu ocheperako chifukwa cha mawonekedwe awo abwino amakina komanso kukhudzidwa kwawo, kuchita gawo lofunikira kwambiri mu MEMS.

Zida Zapamwamba

Ndi chitukuko chaukadaulo, zida zapamwamba monga nanocomposites ndi graphene zikuchulukirachulukira pakugwiritsira ntchito kwawo pamasensa amphamvu afilimu. Zidazi zimafufuzidwa kwambiri chifukwa cha zabwino zake komanso kuthekera kopititsa patsogolo magwiridwe antchito a sensor. Nanocomposites amaphatikiza ubwino wa zipangizo zosiyanasiyana, kupereka mphamvu zapamwamba zamakina ndi ma conductivity, zomwe zingathe kupititsa patsogolo chidwi cha sensa ndi kulimba. Graphene, ndi mawonekedwe ake osanjikiza atomu imodzi komanso mawonekedwe apamwamba amagetsi, amawonedwa ngati chisankho chabwino pazida zam'tsogolo. Sikuti ali ndi ultra-mkulu conductivity komanso amaonetsa kwambiri mawotchi mphamvu ndi elasticity, kusonyeza kuthekera kwakukulu pa chitukuko cha kopitilira muyeso-sensitive pressure sensors.

Zinthu Zakuthupi

Kusankhidwa kwa zida zamagetsi zowonda zamtundu wa mafilimu zimatengera mphamvu zawo zamagetsi, zamakina, komanso kutentha kuti zitsimikizire kuti zikuyenda bwino pansi pazikhalidwe zosiyanasiyana zogwirira ntchito. Mwachitsanzo, masensa omwe amagwiritsidwa ntchito m'malo otentha kwambiri amafunikira zida zomwe zimakhala ndi kukhazikika kwamafuta komanso kukana kwa okosijeni, pomwe ntchito zomwe zimafunikira kukhudzika kwakukulu zimaganizira madulidwe amagetsi ndi mawotchi okhazikika azinthuzo. Poganizira mozama zazinthu zakuthupi izi, okonza amatha kusankha zida zoyenera kwambiri pazosowa zogwiritsira ntchito, kuwonetsetsa kudalirika komanso kulondola kwa masensa m'malo osiyanasiyana ovuta.

Zolinga Zopangira Ma Thin-Film Pressure Sensors

Kulingalira kwa mapangidwe a masensa owonda-kanema kukakamiza kuonetsetsa kuti akugwira ntchito, odalirika, komanso okhazikika pamapulogalamu osiyanasiyana.

Kapangidwe Kapangidwe

Mapangidwe a mapangidwe a masensa owonda-filimu ayenera kuonetsetsa kukhazikika kwa makina ndi kulimba pamene akukhalabe okhudzidwa ndi olondola. Izi zimafuna okonza kuti asamangoganizira zakuthupi za filimu yopyapyala komanso katundu wamakina ndi kupanikizika kwa chilengedwe muzogwiritsira ntchito zenizeni. Mapangidwe a sensor amayenera kupirira zovuta zamakina osiyanasiyana komanso kusintha kwa chilengedwe ndikusunga chizindikiro chokhazikika.

Kumverera

Sensitivity ndiye chinthu chofunikira kwambiri pakupanga ma sensors okakamiza, motengera kusankha kwa zinthu, makulidwe amafilimu ochepa, komanso ukadaulo wopanga. Masensa apamwamba kwambiri amatha kuzindikira kusintha kwa mphindi zochepa, ndikofunikira kuti muyezedwe molondola ndikuwongolera magwiridwe antchito. Kusankhidwa kwa zinthu kumakhudza mwachindunji kukhudzidwa kwa sensa; zida zosiyanasiyana zimakhala ndi makina ndi magetsi osiyanasiyana, oyenera pazosowa zosiyanasiyana zogwiritsira ntchito. Kuchuluka kwa filimu yopyapyala ndi chinthu chofunikira kwambiri; filimuyo imakhala yochepa kwambiri, imakhala ndi mphamvu zambiri, koma izi zikhoza kuchepetsa mphamvu zamakina, zomwe zimafunika kuti pakhale mgwirizano pakati pa kukhudzidwa ndi mphamvu.

Zolondola ndi Zolondola

Kukwaniritsa kulondola kwambiri komanso kulondola muzowonera zowonda-filimu kumafuna kupanga mosamala ndi kupanga njira kuti zitsimikizire kudalirika kwa kuyeza komanso kubwereza. Izi zikuphatikiza kuwongolera ndendende makulidwe ndi kufanana kwa filimu yopyapyala, kusankha magawo oyenera, ndikuwongolera njira zopangira. Kupatuka kulikonse kwakung'ono pakupanga kungakhudze magwiridwe antchito a sensor, kupanga kuwongolera kokhazikika komanso kuyesa kofunikira.

Makhalidwe Antchito Nthawi Yoyankha

Makanema a Thin-film pressure nthawi zambiri amakhala ndi nthawi yoyankha mwachangu, yofunikira pamapulogalamu osunthika omwe amafunikira kuyang'anitsitsa nthawi yeniyeni. Nthawi yoyankha mwachangu imatsimikizira kuti sensa imatha kujambula kusintha kwapanthawi yomweyo, kupereka chithandizo chanthawi yeniyeni pamagwiritsidwe ntchito ngati mafakitale, zida zamankhwala, ndi ndege.

Kukhalitsa

Kusankha zida zoyenera ndikugwiritsa ntchito njira zodalirika zopangira kumapangitsa kulimba kwa masensa amphamvu afilimu, kuonetsetsa kudalirika kwa nthawi yayitali. Kukhalitsa ndikofunikira kuti masensa azitha kugwira ntchito kwanthawi yayitali, makamaka omwe amagwira ntchito m'malo ovuta kwambiri, monga kutentha kwambiri, chinyezi chambiri, kapena malo owononga.

Kukhazikika Kwachilengedwe

Masensa amtundu wa Thin-film amayenera kugwira ntchito mosasinthasintha m'malo osiyanasiyana achilengedwe, kuphatikiza kusinthasintha kwa kutentha, chinyezi, komanso kupsinjika kwamakina. Izi zimafuna masensa kuti akhale ndi kukhazikika kwa chilengedwe, kukhala okhoza kugwira ntchito mkati mwa kutentha kwakukulu, komanso kukhala osakhudzidwa ndi kusintha kwa chinyezi ndi kupsinjika kwa makina. Kusankha kwazinthu ndi kapangidwe ka ma CD kumagwira ntchito yofunika kwambiri pakuwonetsetsa kukhazikika kwachilengedwe kwa masensa.

Kugwiritsa ntchito kwa Thin-Film Pressure Sensors

M'makampani oyendetsa magalimoto, masensa owonda kwambiri amafilimu amagwiritsidwa ntchito m'makina owunikira ma tayala (TPMS) kuti apereke chidziwitso chanthawi yeniyeni ya tayala, kupititsa patsogolo chitetezo ndi magwiridwe antchito. M'makina oyendetsera injini, masensa awa amawunika kuthamanga kwamafuta ndi mpweya, kuwonetsetsa kuti injini ikuyenda bwino komanso ikugwira bwino ntchito. Kuphatikiza apo, makina otetezera magalimoto ngati ma airbags ndi ma braking system amadalira masensa amphamvu afilimu kuti athe kuyeza kuthamanga kwachangu komanso kuyambitsa munthawi yake.

Pazachipatala, masensa othamanga a mafilimu ochepetsetsa amagwiritsidwa ntchito poyang'anira kuthamanga kwa magazi, kupereka miyeso yolondola komanso yosasunthika yofunikira pa chisamaliro cha odwala ndi matenda. Amagwiritsidwanso ntchito m'masensa opangidwa ndi implantable kuti aziwunika mosalekeza zakuthupi, kuwongolera zotsatira za chithandizo cha odwala. Zida zamankhwala zovala, monga zolondolera zolimbitsa thupi komanso zowunikira zaumoyo, zimagwiritsa ntchito masensawa kuti azitsata zofunikira komanso zochitika zakuthupi.

M'gawo lazamlengalenga, masensa owonda kwambiri amakanema amagwiritsidwa ntchito powunikira kuthamanga kwa kabati, kuwonetsetsa kuti kupanikizika kwa kanyumba kabwinoko kumatonthoza okwera komanso chitetezo. Amagwiritsidwanso ntchito powunika zaumoyo wamapangidwe, omwe amatha kuzindikira zovuta zomwe zingachitike zisanakhale zovuta. Kuphatikiza apo, masensa awa ndi ofunikira kwambiri pamakina owongolera zachilengedwe, kuwonetsetsa kuti zinthu zikuyenda bwino kwa ogwira ntchito ndi zida.

M'mafakitale, masensa owonda-filimu amagwiritsidwa ntchito poyang'anira ndondomeko yolondola, kuonetsetsa kuti ntchito yabwino ndi yogwira ntchito. Makina a robotiki amadalira masensa awa kuti azitha kuyankha komanso kumva kupanikizika, kukulitsa magwiridwe antchito ndi kuthekera kwawo. Machitidwe a chitetezo cha mafakitale amagwiritsanso ntchito makina osindikizira a mafilimu ochepa kwambiri kuti azindikire ndi kuyankha kusintha kwapanikizidwe, kuteteza ngozi ndi kuonetsetsa chitetezo cha ogwira ntchito.

Mafunso Ofunsidwa Kawirikawiri

Kodi ubwino waukulu wa masensa a mafilimu opyapyala ndi ati?

Makanema amtundu wa Thin-film amapereka chidwi kwambiri, miniaturization, komanso kudalirika kowonjezereka, kuwapangitsa kukhala abwino pazogwiritsa ntchito zosiyanasiyana. Kumverera kwawo kwakukulu kumawathandiza kuzindikira kusintha kwa mphindi zochepa, mawonekedwe a miniaturized amawapangitsa kukhala oyenera kugwiritsira ntchito malo opanda malo, ndipo kudalirika kowonjezereka kumapangitsa kuti ntchito ikhale yokhazikika kwa nthawi yayitali m'madera ovuta.

Kodi masensa amtundu wochepa thupi amasiyana bwanji ndi masensa akale?

Masensa amtundu wa Thin-film ndi olondola kwambiri, ophatikizika, ndipo nthawi zambiri amakhala olimba kuposa masensa achikhalidwe ambiri. Amapereka magwiridwe antchito abwino pamapulogalamu omwe amafunikira, amatha kugwira ntchito mkati mosiyanasiyana kutentha ndi kupanikizika, ndipo amakhala ndi chidwi chochulukirapo komanso kuthamanga kwambiri. Makhalidwewa amapangitsa masensa amafilimu opyapyala kukhala opambana pamapulogalamu ambiri ofunikira kwambiri.

Kodi ndi zinthu ziti zomwe zimagwiritsidwa ntchito kwambiri mu sensa ya mafilimu opyapyala?

Zida zodziwika bwino zimaphatikizapo zitsulo monga golide ndi platinamu, ma semiconductors ngati silicon, ndi zida zapamwamba ngati graphene. Golide ndi platinamu amagwiritsidwa ntchito kwambiri pakuwongolera kwawo bwino komanso kukana kwa dzimbiri mu maelekitirodi a sensa. Silicon imagwiritsidwa ntchito kwambiri m'mafilimu owonda kwambiri a semiconductor chifukwa cha makina ake abwino komanso mawonekedwe amagetsi, pomwe graphene imawonedwa ngati yabwino kwa zida zam'tsogolo za sensor chifukwa champhamvu zake zamagetsi komanso mphamvu zamakina.

Ndi mafakitale ati omwe amapindula kwambiri ndi masensa amphamvu amafilimu opyapyala?

Magalimoto, zamankhwala, zakuthambo, zamagetsi ogula, ndi mafakitale opanga makina amapindula kwambiri ndi masensa amphamvu amafilimu. M'makampani opanga magalimoto, masensa awa amagwiritsidwa ntchito poyang'anira kuthamanga kwa tayala ndi kasamalidwe ka injini; m'chipatala, amagwiritsidwa ntchito poyang'anira kuthamanga kwa magazi ndi masensa omwe amaikidwa; m'gawo lazamlengalenga, amagwiritsidwa ntchito poyang'anira kuthamanga kwa kabati ndi kuyang'anira thanzi labwino; pamagetsi ogula, amakulitsa luso la ogwiritsa ntchito zida zanzeru; komanso mu makina opanga mafakitale, amagwiritsidwa ntchito poyang'anira ndondomeko ndi robotics.

Kodi ndi njira ziti zopangira zomwe zimagwiritsidwa ntchito popanga ma sensor amafilimu opyapyala?

Njira zodziwika bwino ndi monga sputtering, chemical vapor deposition (CVD), physical vapor deposition (PVD), ndi atomic layer deposition (ALD). Njirazi zimatha kuwongolera ndendende makulidwe, kufanana, ndi kapangidwe ka filimu yopyapyala, kuwonetsetsa kuti sensa imagwira ntchito komanso kudalirika. Sputtering ndi njira yomwe imagwiritsidwa ntchito kwambiri popangira zitsulo zopyapyala zamafilimu; Njira za CVD ndi PVD zimagwiritsidwa ntchito poyika ma semiconductors ndi zida zotetezera; ALD imatha kuwongolera makulidwe a makanema owonda pamlingo wa atomiki, oyenera kukonzekera makanema owonda kwambiri.

Zolozera:

1.Ohring, M. (2001). "Zakuthupi Sayansi ya Mafilimu Ochepa." Academic Press.

Nthawi yotumiza: Jun-28-2024